Home Data Center Services Liquid Cooling Liquid Cooling Solutions

Liquid Cooling Solutions

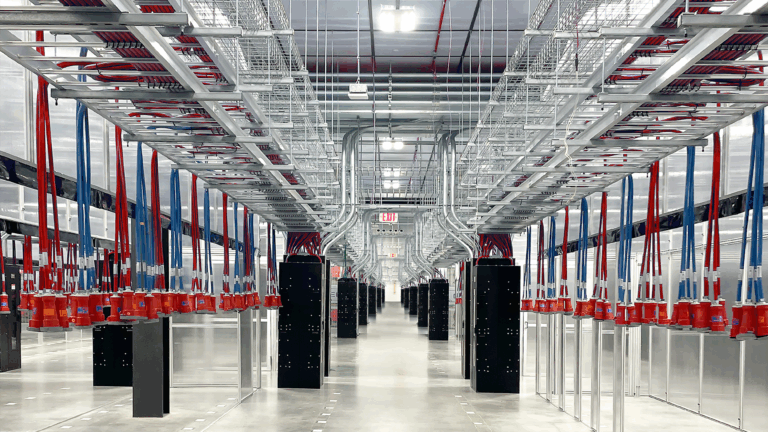

Liquid Cooling Solutions for AI & HPC Data Centers

Every AI and HPC environment is different. And so are its cooling demands. That’s why Compu Dynamics doesn’t offer one-size-fits-all solutions. We deliver integrated, vendor-neutral solutions built around your workloads, infrastructure, and long-term goals.

Whether you’re deploying direct-to-chip cold plates, rear door heat exchangers (RDHx), or immersion systems, our team works across all major OEMs to design, source, install, and support the optimal system for your facility.

From technology selection and white space integration to commissioning and ongoing maintenance, we are your one-stop shop for high-performance liquid cooling.

Liquid Cooling Technologies We Support

We design and deploy the full spectrum of AI- and HPC-ready liquid cooling technologies:

Direct-to-Chip Cold Plate Cooling

Precision cooling for high-wattage CPUs and GPUs, integrated with custom manifolds and CDUs.

Rear Door Heat Exchangers (RDHx)

Ideal for high-density retrofits and colocated environments – max cooling, minimal disruption.

Immersion Cooling Systems

Fully submerge servers in dielectric fluid for ultra-efficient thermal performance and noise reduction.

Hybrid Approaches

Combine cold plate and RDHx, or immersion and air cooling, for flexible deployment strategies.

Liquid Cooling Installation Services

Compu Dynamics delivers turnkey installation services for your liquid cooling TCS – from white space to mechanical room. With self-performing capabilities and in-house engineers trained across all major OEMs, we ensure precise integration of critical components including CDUs, manifolds, piping, and controls.

Our liquid cooling installation process follows ASHRAE-recommended best practices for Technical Cooling Systems, including isolated secondary loops, ultra-clean fluid paths, zone-based leak detection, and commissioning under simulated load. Whether you’re deploying in a greenfield site or retrofitting an active data hall, we help bring your system online — cleanly, safely, and with full confidence.

Our Installation Services Include:

- Design consultation and capacity planning

- Procurement and deployment of CDUs (in-rack and floor-mounted)

- Piping system design, fabrication, and installation (overhead and underfloor)

- In-rack manifold and header integration

- Coolant and fluid management systems with filtration and flushing

- Leak detection systems, drip pans, and zone-based isolation

- Infrastructure assessments (weight load, ceiling support, non-ferrous piping)

- BMS and sensor integration (temperature, pressure, flow, leak detection)

- Installation of smart valves, filters, and bypass systems

- Equipment startup, load testing, and full system commissioning

We also handle permitting, inspection scheduling, and equipment validation—making it easy to bring your liquid cooling project online with confidence.

Liquid Cooling Testing, Commissioning & Maintenance

Compu Dynamics provides full lifecycle support to ensure your liquid cooling system performs as designed – day one and every day after. From functional commissioning and flow validation to ongoing fluid management and emergency response, our services are built around reliability, compliance, and uptime.

We follow ASHRAE commissioning and maintenance best practices for Technical Cooling Systems, including staged system validation, coolant quality monitoring, and sensor calibration. With packaged service plans, advanced diagnostics, and 24/7 response capabilities, we keep your TCS running at peak efficiency — so your workloads stay cool and your operations stay uninterrupted.

Our Testing & Maintenance Services Include:

- Functional testing and system commissioning

- Coolant and fluid sampling, analysis, and filtration

- Flow balancing and inlet/outlet temperature validation

- BMS integration testing and sensor calibration (temp, pressure, flow, leak)

- Leak detection testing and zone-based isolation validation

- Regular inspections for component wear and inefficiencies

- Service record management for compliance and audit support

- Coolant remediation and non-conformance corrective actions

- Warranty support and OEM coordination

- 24/7 emergency diagnostics, Smart Hands, and onsite response via CompuCare™

Liquid Cooling Testing, Commissioning & Maintenance

Compu Dynamics provides full lifecycle support to ensure your liquid cooling system performs as designed – day one and every day after. From functional commissioning and flow validation to ongoing fluid management and emergency response, our services are built around reliability, compliance, and uptime.

We follow ASHRAE commissioning and maintenance best practices for Technical Cooling Systems, including staged system validation, coolant quality monitoring, and sensor calibration. With packaged service plans, advanced diagnostics, and 24/7 response capabilities, we keep your TCS running at peak efficiency — so your workloads stay cool and your operations stay uninterrupted.

Our Testing & Maintenance Services Include:

- Functional testing and system commissioning

- Coolant and fluid sampling, analysis, and filtration

- Flow balancing and inlet/outlet temperature validation

- BMS integration testing and sensor calibration (temp, pressure, flow, leak)

- Leak detection testing and zone-based isolation validation

- Regular inspections for component wear and inefficiencies

- Service record management for compliance and audit support

- Coolant remediation and non-conformance corrective actions

- Warranty support and OEM coordination

- 24/7 emergency diagnostics, Smart Hands, and onsite response via CompuCare™