Home Data Center Services Liquid Cooling Infrastructure Upgrades

Infrastructure Upgrades

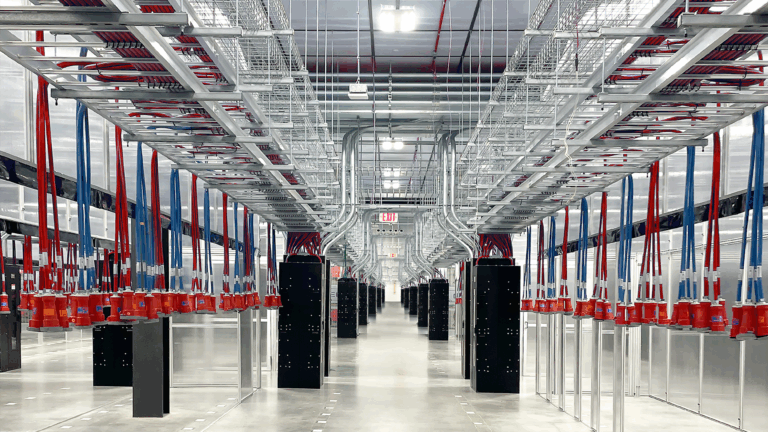

Modernize for AI, Without Rebuilding from Scratch

Legacy cooling infrastructure was never intended to handle the thermal output of today’s AI and HPC clusters, where rack power densities can exceed 100 kW. That doesn’t mean you need a full facility overhaul. Compu Dynamics delivers targeted liquid cooling upgrades—integrating seamlessly into your existing infrastructure—so you can scale performance without the disruption of a complete rebuild.

Liquid Cooling Infrastructure Upgrade Capabilities

Our approach aligns with ASHRAE best practices for Technical Cooling Systems (TCS) and incorporates proven engineering methods to maximize performance. We design upgrades that isolate and protect the primary chilled water loop, ensure ultra-clean secondary loops, optimize CDU capacity, and deploy precise thermal controls for predictable, efficient operation.

Our Liquid Cooling Upgrade Capabilities Include:

- Secondary Cooling Loop Installation: Design and implement isolated secondary loops for direct-to-chip or RDHx deployments—maintaining fluid purity, temperature stability, and redundancy (N+1 or greater) without impacting the primary system.

- CDU Integration & Optimization: Install or expand coolant distribution units (in-rack or floor-mounted) to match rack density requirements, balance thermal loads across PODs, and enable future expansion with spare loop taps.

- White Space Preparation: Engineer overhead or underfloor piping routes, containment systems, and in-rack manifolds to ASHRAE-recommended flow rates and pressure drops, ensuring optimal thermal transfer and serviceability.

- Smart Controls & Monitoring: Deploy integrated sensors for temperature, pressure, and flow—combined with leak detection and automated isolation valves—to provide real-time telemetry through your BMS or DCIM platform.

- Scalable Upgrade Paths: Design modular, phase-ready infrastructure that supports future liquid cooling technologies and platform changes without costly redesigns or downtime.

Our Liquid Cooling Upgrade Capabilities

Our approach aligns with ASHRAE best practices for Technical Cooling Systems (TCS) and incorporates proven engineering methods to maximize performance. We design upgrades that isolate and protect the primary chilled water loop, ensure ultra-clean secondary loops, optimize CDU capacity, and deploy precise thermal controls for predictable, efficient operation.

Secondary Cooling Loop Installation

Design and implement isolated secondary loops for direct-to-chip or RDHx deployments—maintaining fluid purity, temperature stability, and redundancy (N+1 or greater) without impacting the primary system.

CDU Integration & Optimization

Install or expand coolant distribution units (in-rack or floor-mounted) to match rack density requirements, balance thermal loads across PODs, and enable future expansion with spare loop taps.

White Space Preparation

Engineer overhead or underfloor piping routes, containment systems, and in-rack manifolds to ASHRAE-recommended flow rates and pressure drops, ensuring optimal thermal transfer and serviceability.

Smart Controls & Monitoring

Deploy integrated sensors for temperature, pressure, and flow—combined with leak detection and automated isolation valves—to provide real-time telemetry through your BMS or DCIM platform.

Scalable Upgrade Paths

Design modular, phase-ready infrastructure that supports future liquid cooling technologies and platform changes without costly redesigns or downtime.

Our approach aligns with ASHRAE best practices for Technical Cooling Systems (TCS) and incorporates proven engineering methods to maximize performance. We design upgrades that isolate and protect the primary chilled water loop, ensure ultra-clean secondary loops, optimize CDU capacity, and deploy precise thermal controls for predictable, efficient operation.

Our Liquid Cooling Upgrade Capabilities Include:

- Secondary Cooling Loop Installation: Design and implement isolated secondary loops for direct-to-chip or RDHx deployments—maintaining fluid purity, temperature stability, and redundancy (N+1 or greater) without impacting the primary system.

- CDU Integration & Optimization: Install or expand coolant distribution units (in-rack or floor-mounted) to match rack density requirements, balance thermal loads across PODs, and enable future expansion with spare loop taps.

- White Space Preparation: Engineer overhead or underfloor piping routes, containment systems, and in-rack manifolds to ASHRAE-recommended flow rates and pressure drops, ensuring optimal thermal transfer and serviceability.

- Smart Controls & Monitoring: Deploy integrated sensors for temperature, pressure, and flow—combined with leak detection and automated isolation valves—to provide real-time telemetry through your BMS or DCIM platform.

- Scalable Upgrade Paths: Design modular, phase-ready infrastructure that supports future liquid cooling technologies and platform changes without costly redesigns or downtime.