Two top priorities for every data center are sustaining uninterrupted uptime for their customers and ensuring the safety of their employees. Successfully meeting those goals requires continuous scanning and inspecting for electrical hot spots in the data center’s electrical equipment that could potentially – if left unresolved – result in equipment malfunction and serious safety hazards. This is the reason why Infrared Thermography (IR Imaging) is critical to eliminate data center downtime.

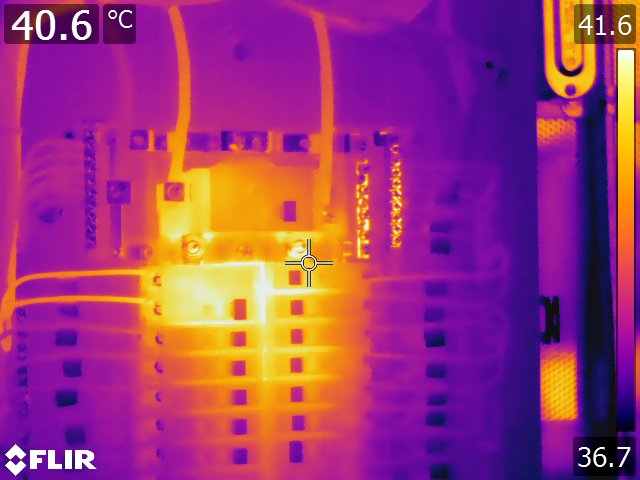

If breakers are overloaded or connections are loose, resistance can occur in electrical gear, which inevitably will lead to heat buildup, causing the failure of critical systems. With workload and power demands at an all-time high, data centers must be on the lookout for these signs to avoid downtime for their customers and eliminate threats to employee safety, such as life-threatening arc flashes.

What is Infrared Thermography (IR Imaging)?

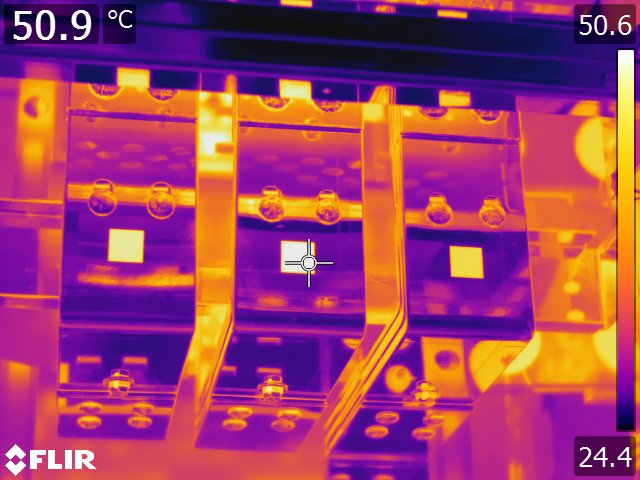

To monitor and sense heat buildup and resistance within white space electrical equipment, data centers are turning to infrared (IR) thermography technologies. IR thermography scanning is performed by qualified electricians who take photographs of equipment with specialized cameras that can “see” in the infrared spectrum and detect heat that is invisible to the human eye.

IR thermography photographs of data center gear are essentially snapshots in time that enable technicians to identify abnormal hot spots. By performing regular IR thermography scans, data centers are better equipped to catch and fix electrical issues before they reach points of failure, causing downtime and safety risks.

Last March, the National Fire Protection Association (NFPA) officially standardized IR thermography as an annual requirement for electrical maintenance. For data centers, that means every switch gear, disconnect, busway, panel, and any component that provides building or equipment power must be IR scanned at least once a year.

Though the NFPA recommends annual scans, we at Compu Dynamics recommend that critical systems be inspected more frequently. According to Uptime Institute’s annual survey, 43 percent of data center outages are related to power failures. Critical systems experience heavier workloads and endure greater electrical vibrations than other equipment, which can lead to the loosening of connections, screws, and bolts – eventually resulting in overheating.

And it’s not just electrical vibrations that can cause loose connections. Vibration resulting from the running of air conditioning systems or employees walking on floors nearby all contribute to the forces that can loosen electrical connections over time.

Cost-Savings and Continuity Through IR Thermography

IR thermography scanning delivers many benefits to data center owners. First, it enables technicians to identify heat resistance early, giving data center operators the power to repair equipment before they reach a state of failure or malfunction. Proactive detection, prevention, and maintenance of electrical hotspots allows data centers to minimize the chances of downtime.

If there is one scenario that all data centers want to avoid, it is the downtime of their services. Regular IR scanning will ensure that all equipment deficiencies are caught and can be addressed before they evolve into greater issues.

The second benefit of IR thermography is that it provides a safe method of scanning for abnormal heat resistance. It probably goes without saying, but it is not practical to rely on physical touch to sense heat buildup in data center equipment. Directly touching electrical equipment is extremely hazardous and life-threatening.

Overloaded breakers and loose connections are both common sources of heat resistance that could potentially lead to an arc flash. Having regular IR scans can identify these situations early enough to avoid dangerous arc flash scenarios and keep data center employees healthy and safe.

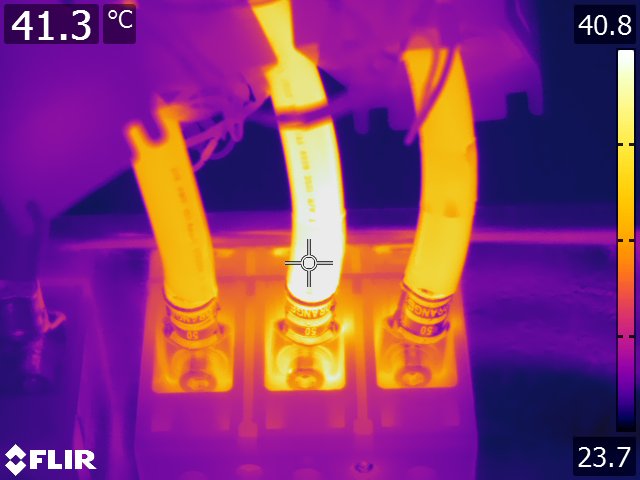

And IR scans are not just recommended for legacy systems. Even brand-new equipment should be immediately scanned to identify defects or issues stemming from the manufacturer or the installation process. If caught early, facility operators can ensure that any faulty connections that are present after a manufacturer installation are addressed in a timely manner, eliminating any likelihood of electrical malfunction, failure, or an arc flash.

IR scans can also result in major budget savings by avoiding operational disruption and loss of revenue. Revealing major equipment flaws as early as possible allows data centers to address defects with the manufacturer directly – in the case of a brand-new installation – and prevent the shutdown of operations due to massive and invasive repairs that would otherwise be required.

IR Scanning Under the Right Conditions

An IR thermography scan must be performed during peak operating times by qualified electricians who are wearing the proper safety equipment. Inspections are recommended to be executed during the busiest hours of operation to capture all heat that is present during a max load. If IR scans are performed during off-peak hours, IR cameras will not be capturing true and accurate readings of the heat that could be symptomatic of potential equipment issues.

In most cases, electricians performing the IR scans will not only take an infrared photograph of electrical equipment but also provide a traditional picture to accompany it, allowing the customers to see the conditions of their systems in both the IR spectrum as well as what the human eye can see. This is extremely helpful for customers to see both representations and fully understand what the IR image reveals.

Having IR snapshots of those systems throughout the year equips data center owners with a granular knowledge of the current conditions and health of critical systems. It also enables them to develop a more precise maintenance plan to keep equipment finely tuned and healthy, all while avoiding points of failure, downtime, and ensuring the utmost safety of their staff.

Compu Dynamics’ customers that leverage our IR thermography services can rest assured that our certified electricians are equipped with the proper tools to conduct thorough IR scans, document every piece of equipment that is evaluated, and deliver a robust feedback report for our clients refer to when moving forward with maintenance and upkeep. We provide actionable recommendations for any issues we discover, and our customers always have the option to have our team remediate any problems we discover after inspection.